Wiper Trim Seals by FlexSeals

Engineered for Performance, Built for Reliability

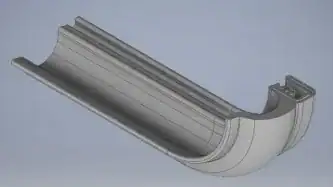

Precision Rubber Wiping Flap Seals for Movement, Weather, and Extreme Environments

FlexSeals (FS USA) designs and manufactures high-performance wiper trim seals built for durability, flexibility, and long-term sealing in dynamic environments. These co-extruded profiles are trusted by manufacturers across a range of industries, including transportation, agriculture, marine, construction, RVs, and off-road vehicles.

Our rubber wiper flap seals combine a dense edge trim with a flexible EPDM wiping element, forming a tight, consistent seal even during repeated motion, temperature fluctuations, and exposure to dust, water, and vibration. Whether protecting slide-out rooms, door edges, or equipment enclosures, our wiper trim seals provide the rugged, adaptable sealing performance industrial applications demand.

FS USA

Built for Motion-Heavy Applications

Wiper trim seals are uniquely engineered to maintain contact during motion—ideal for components that open, slide, or vibrate. Our rubber wiping flap seals are designed to flex and rebound reliably, helping reduce contamination, noise, and mechanical wear over time.

Common Uses Include:

- RV slide-outs and compartment doors

- Transit vehicle access panels

- Agricultural machinery with moving panels

- Marine hatches and outdoor enclosures

- Heavy equipment cabins and storage units

With easy, edge-gripping installation and optional internal wire or metal carriers, these seals stay firmly in place under pressure and vibration.

Premium Materials for Harsh Conditions

Unlike many wiper trim seals that crack or deform under UV, ozone, or extreme temperatures, FlexSeals uses high-grade materials formulated for resilience and longevity. We offer:

- EPDM Rubber – Excellent weather, UV, and ozone resistance

- PVC and Sponge Rubber – Flexible, cost-effective options for specific applications

- Dual-Durometer Compounds – Combine soft and firm materials for optimal compression and fit

Our co-extruded designs allow different materials to be integrated into one continuous profile, delivering consistent compression even across uneven surfaces.

Advanced Features and Custom Options

FlexSeals’ wiper trim seals can be configured to meet a wide range of application requirements. From standard trims to complex multi-component assemblies, our seals are made to perform where others fail.

Key Features:

- Co-extruded wiper and trim for flexible yet secure sealing

- Metal-reinforced edge trims for enhanced grip and dimensional stability

- Optional flocking or anti-friction coatings to reduce wear

- Adhesive backing options for simplified installation

- EMI shielding capabilities for sensitive enclosures

- Tool-free installation with reliable compression seal

Our profiles can also be tailored with custom lengths, vulcanized corners, or specific material combinations to solve unique engineering challenges.

Made in the USA—Backed by Engineering Support

All FlexSeals wiper trim seals are proudly manufactured in the USA, ensuring fast lead times, strict quality control, and responsive customer support. Our team works directly with OEMs, engineers, and purchasing managers to deliver sealing solutions that fit seamlessly into production lines and product designs.

Whether you’re upgrading an existing component or developing a new enclosure system, we’ll help you choose the right seals for your wiping flaps. We provide materials, and installation methods for long-term reliability and ease of use.

Seal Smarter With FlexSeals

Choose from our catalog of standard rubber wiper flap trim profiles or collaborate with our engineering team to create a custom solution. At FlexSeals, we don’t just manufacture seals—we engineer confidence.

Contact us today to request a quote or explore your project needs with our specialists.